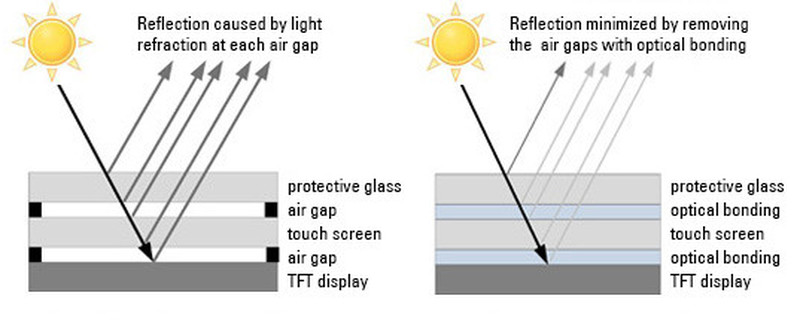

Optical bonding is the process of laminating a cover glass or touch screen directly onto an LCD cell by eliminating air gaps with a transparent adhesive. Materials such as silicone gel, epoxy, or urethane are used to fill the space between the layers, enhancing durability, optical clarity, and environmental resistance.

Why choose FORTEC Egypt for Optical Bonding?

At FORTEC Egypt, we take pride in delivering the highest level of service, and our optical bonding process is no exception. With years of hands-on experience, our in-house experts apply optical bonding with precision and consistency—ensuring superior display performance tailored to your application needs.

Our state-of-the-art facilities are central to delivering optical bonding services at the highest possible standard. Every step of the process is carried out with precision and care, and we’re pleased to offer sample units—so you can experience the quality firsthand.

With over 15 years of industry experience, we take pride in offering a service that combines technical expertise with flexibility, allowing us to meet your unique optical bonding and display requirements with ease.

How does the VacuBond® optical bonding process work?

Using our VacuBond® technology, various display components are bonded together using high-performance Opto a-Gel in a cleanroom environment. This process eliminates air gaps between layers and reduces surface reflections by up to 99%, resulting in significantly improved readability, contrast, and color vibrancy.

Displays bonded using VacuBond® maintain outstanding visibility—even in bright, outdoor conditions—ensuring consistent performance and optical clarity in the most demanding environments.

Optical Bonding Downloads

Optical bonding clients tend to prefer the longer life PREMIUM industrial panels.

Please see this range is with 5 years longevity statements.

Why VacuBond®?

In today’s display market, many manufacturers now offer TFT displays with integrated PCAP touch screens as standard. However, specific applications often require a custom front glass—either for enhanced protection or to align with a unique design aesthetic.

Our VacuBond® optical bonding process provides the ideal solution. With the recent addition of two large-format bonding machines, we are now capable of bonding TFT displays up to 32", expanding our capacity to meet a broader range of customer needs.

We offer complete touch display solutions, including custom protective glass, and carry out the optical bonding process with zero optical defects—ensuring premium quality and performance.

What are the benefits of Optical Bonding/VacuBond®?

- Increased vibration and shock resistance

- Enhanced contrast and readability

- Elimination of condensation and fogging

- Zero contamination from dust or dirt

- Improved heat dissipation through the front glass

What can be optically bonded using the VacuBond®process?

- TFT displays with sizes up to 32”

- Cover glass applied to TFT displays featuring integrated PCAP touch

- PMMA or acrylic glass components

- Any type of touchscreen and/or protective glass

- The rear surface of the TFT cell to remove internal air gaps

- Direct integration into housings or bezels

- Modern TFT displays without a rigid frame or housing

What types of display can be bonded?

When it comes to optical bonding, surface flatness is key. For a successful bond, both the front of the LCD and the rear of the filter must be flat. Despite this requirement, the vast majority of displays are suitable for bonding. At FORTEC Egypt, we conduct a precise material-layer adhesion angle test to determine bond compatibility and ensure optimal results.

What are the different methods of Optical Bonding?

There are two different methods of Optical Bonding. LOCA, often referred to as wet bonding, is the more traditional method. While it has played a major role in advancing optical bonding technology, it comes with limitations. Rework is only possible before the adhesive cures, and the curing process itself is time-consuming. Additionally, LOCA requires a manual 'dam' to contain the liquid silicone, making it a labor-intensive option.

Developed to meet the high-volume, high-consistency demands of devices like tablets and smartphones, dry bonding uses a vacuum process to apply a silicone sheet between layers. This method allows multiple displays to be bonded simultaneously using a multi-cavity jig, offering greater efficiency, speed, and uniformity.

Which industries are most suited to Optical Bonding?

Optical bonding is ideally suited to a wide range of industries, particularly those requiring high-performance display solutions. It is especially beneficial in sectors that rely on rugged displays for use in high-reliability environments or where screens must remain clearly visible in bright ambient light. The process is particularly effective for devices operating outdoors or in areas with intense lighting, where clarity and durability are paramount.

Typically, Optical Bonding is used in and widely adopted by the military, marine, medical, transportation, and retail sectors.

Can the process of Optical Bonding be reversed?

Yes, dry bonding can absolutely be reversed. Since the VacuBond® process does not require curing, the bond can be undone at any point during the product’s lifecycle. This sets it apart from traditional wet bonding methods, which are typically irreversible once the adhesive has cured.

Tempering/Pre-Aging Heating Cabinets

Our head office in Munich is equipped with specialized industrial heating cabinets, allowing us to offer a pre-aging and tempering service as part of our capabilities.

Modules up to 21.5” in size can be exposed to temperatures ranging from +30°C to +300°C. This process allows us to identify potential weak points early on and helps prevent future equipment failures.

We can carry out experiments over several days, tailored to meet your specific temperature requirements.

Optical Bonding Service

Through our head office, FORTEC Integrated in Germering, we offer our VacuBond® optical bonding service for any display—whether part of our product range or not—up to a size of 32”.

Not only do we operate a production facility in Germering, but we also maintain an identical setup at our American subsidiary, FORTEC USA. In response to growing demand for our optical bonding services, we have expanded our capabilities with additional production facilities—one in Dysina/Pilsen, Czech Republic, and another in Ronkonkoma, New York.